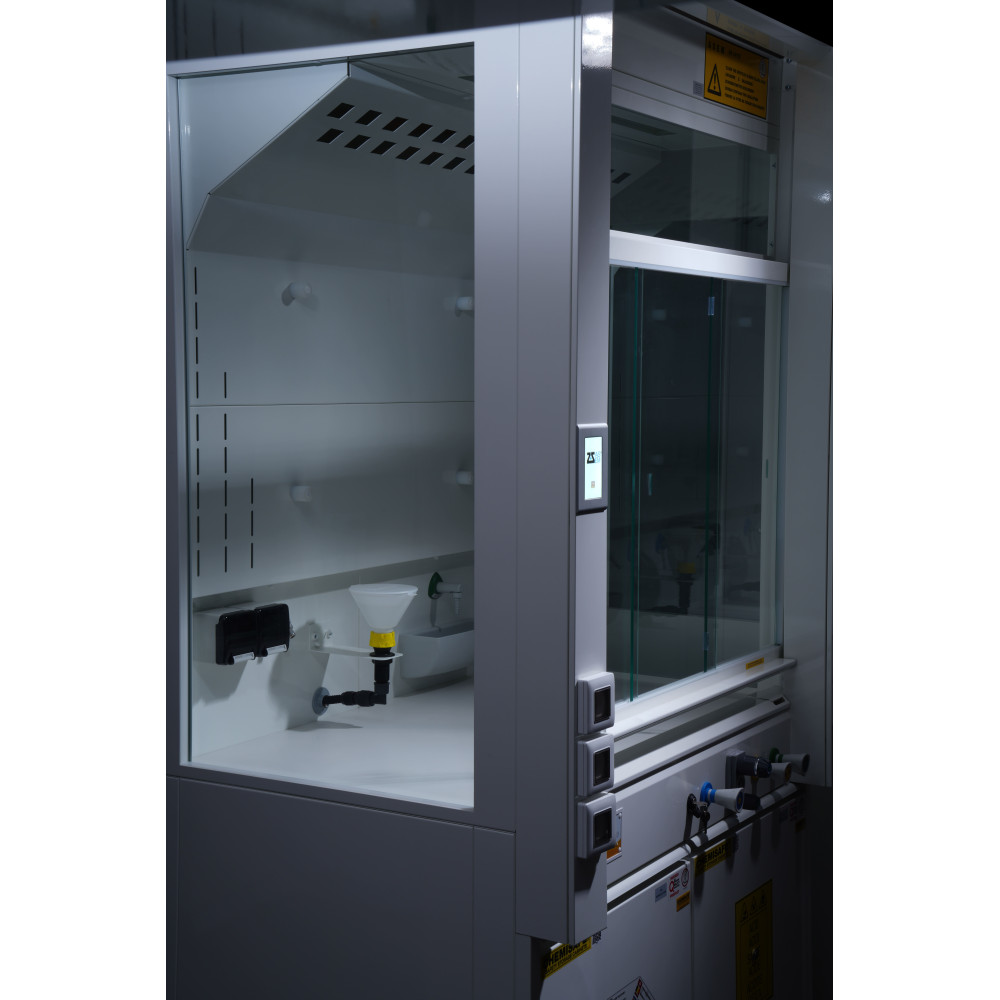

ASEM FUME EXTRACTION HOOD - KRISTAL SERIES CLASS 0

close

R1100342

ASEM FUME EXTRACTION HOOD - KRISTAL SERIES CLASS 0

All of our ASEM® fume extraction hoods are factory tested for containment index and all certified in accordance with EN 14175 2-3-4-5-6-7 and UNI TS 11710 standards.

HOOD WITH DOUBLE EXTRACTION SYSTEM AND V.A.V. DEVICE CERTIFIED ACCORDING TO EN 14175-2-3-5-6 BY BUREAU VERITAS.

USAGE

Collective protection device for the user certified according to EN 14175 - UNI TS 11710 standards.

Extraction of vapors and dust from the working volume to ensure that no concentration of chemicals reaches the operator or the laboratory.

Prevention of the formation of an explosive atmosphere in the working volume.

Protection against the projection of chemical substances.

Chemical fume hoods are not suitable for handling biological agents or microorganisms.

Fire resistance class "1."

STRUCTURE

Frame made of acid-resistant painted steel (outside the extraction chamber).

Side panel split into two parts to simplify assembly and maintenance procedures.

Fully glazed side for maximum operator visibility.

This design ensures maximum performance in terms of airflow and maximum safety for the user and the environment. Inside, a double extraction system promotes air flow at multiple points, favoring the extraction of "heavier" vapors.

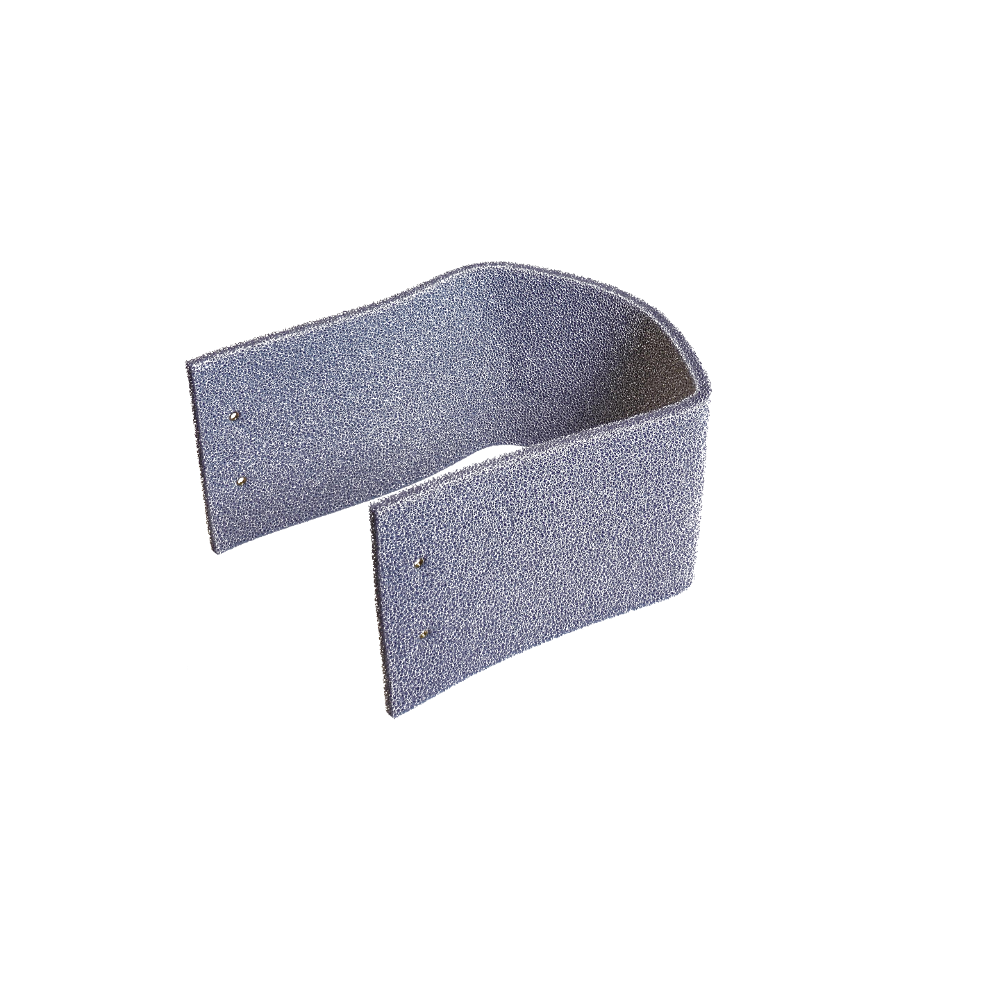

Built with steel elements, in interdependent modules that can be assembled and mechanically connected, allowing interchangeability or replacement of individual elements. The sides, rear panel, double extraction, and ceiling are made from galvanized steel sheets of 15/10 - 10/10 mm thickness, cold pressed and painted, with a degreasing treatment, followed by an initial epoxy primer application and two subsequent applications of thermosetting powders of at least 90 microns, where the enamel undergoes drying and curing in a thermal oven at 210°C and merges with the metal part.

Powders with pigment color WHITE RAL 9010.

The quality and adhesion of the coating are verified according to UNI EN ISO 12944. Hexagonal head steel screws allow for quick assembly of the various components, creating a particularly solid and robust bearing structure. Adjustable anti-acid material feet at the base allow leveling of the structure.

The Kristal hood guarantees the maximum work surface size, with the same external dimensions, by using standard worktops of 1500 x 750 mm or larger.

The monolithic stoneware top is completely detached from the hood and can be removed for replacement or maintenance without dismantling any part of the structure.

Made from a single large plate with raised perimeter edges, it is a seamless body without joints or gaps. It is made by molding a mixture of clays, pure quartz, kaolin, and feldspathic fluxes, with a light gray anti-reflective glaze and a single firing at 1300°C, giving the enamel excellent chemical resistance. After firing, it has a perfectly smoothed, smooth, uniform surface that is easy to wash and decontaminate, and resistant to chemical agents, solvents, thermal, and mechanical stress.

It is resistant to the corrosion of acids, alkalis, salts, and solvents at all concentrations, with poor resistance to hydrofluoric acid and strong hot alkalis.

Monolithic stoneware tops have high mechanical resistance, good resistance to thermal shocks, and are non-flammable.

Characteristics comply with DIN 12916 standards. The distinctive features of the monolithic stoneware top are: self-supporting, no joints, high chemical inertia, easy replacement, easy cleaning, decontamination, and pest control.

RISE AND FALL SYSTEM WITH FRONT COUNTERWEIGHT

Steel frame with epoxy coating, plastic sliding guides, and silencer.

6 mm thick safety glass in 3 elements that also slide horizontally.

Aerodynamic handle to optimize the airflow.

Vertical counterweights on the front rectangular deflectors in powder-coated steel, hidden by removable panels (110x110 mm), allowing easy access to the pulleys and the toothed belt.

Allows for the integration of electrical outlets and the hood control panel.

The toothed belt is made of plastic with an anti-friction device for quiet operation.

Safety device (anti-fall system) with immediate locking of the rise-and-fall system in case of imbalance or breakage of the belt.

Mechanical stops at a height of 45 cm with manual unlocking for opening the front panel in compliance with regulations.

FRONT MOUNTED TECHNICAL DRAWER

Integrated technical drawer under the work surface, designed to house gas and fluid faucets, as well as the hood's electronics with separate compartments for each component.

Watertight drawer for optimal protection of equipment in case of accidental liquid spillage.

Ultra-quiet nylon sliding guides ensure almost complete opening of the drawer for easy access to the equipment.

Easy and quick access to the electronics, alarms, electrical and fluid connections through a dedicated and easily accessible compartment (with an included user manual in the drawer), highly appreciated by maintenance teams.

Dimensions: 1800 x 750 mm.

With a polypropylene basin of 300 x 150 mm on the right, raised to avoid accidental discharge of spilled products.

Side panels with Class 0 CP glass.

Large 6 mm shatterproof safety glass provides better internal visibility under safe conditions. It can be easily removed from the outside by removing the fixing profiles.

2 EE UNEL 10/16° IP55 outlets and dedicated magnetothermal switch.

Internal LED lighting.

The extraction point is located on the top of the hood: flange/collar with a diameter of 250 mm.

HOOD WITH DOUBLE EXTRACTION SYSTEM AND V.A.V. DEVICE CERTIFIED ACCORDING TO EN 14175-2-3-5-6 BY BUREAU VERITAS.

USAGE

Collective protection device for the user certified according to EN 14175 - UNI TS 11710 standards.

Extraction of vapors and dust from the working volume to ensure that no concentration of chemicals reaches the operator or the laboratory.

Prevention of the formation of an explosive atmosphere in the working volume.

Protection against the projection of chemical substances.

Chemical fume hoods are not suitable for handling biological agents or microorganisms.

Fire resistance class "1."

STRUCTURE

Frame made of acid-resistant painted steel (outside the extraction chamber).

Side panel split into two parts to simplify assembly and maintenance procedures.

Fully glazed side for maximum operator visibility.

This design ensures maximum performance in terms of airflow and maximum safety for the user and the environment. Inside, a double extraction system promotes air flow at multiple points, favoring the extraction of "heavier" vapors.

Built with steel elements, in interdependent modules that can be assembled and mechanically connected, allowing interchangeability or replacement of individual elements. The sides, rear panel, double extraction, and ceiling are made from galvanized steel sheets of 15/10 - 10/10 mm thickness, cold pressed and painted, with a degreasing treatment, followed by an initial epoxy primer application and two subsequent applications of thermosetting powders of at least 90 microns, where the enamel undergoes drying and curing in a thermal oven at 210°C and merges with the metal part.

Powders with pigment color WHITE RAL 9010.

The quality and adhesion of the coating are verified according to UNI EN ISO 12944. Hexagonal head steel screws allow for quick assembly of the various components, creating a particularly solid and robust bearing structure. Adjustable anti-acid material feet at the base allow leveling of the structure.

The Kristal hood guarantees the maximum work surface size, with the same external dimensions, by using standard worktops of 1500 x 750 mm or larger.

The monolithic stoneware top is completely detached from the hood and can be removed for replacement or maintenance without dismantling any part of the structure.

Made from a single large plate with raised perimeter edges, it is a seamless body without joints or gaps. It is made by molding a mixture of clays, pure quartz, kaolin, and feldspathic fluxes, with a light gray anti-reflective glaze and a single firing at 1300°C, giving the enamel excellent chemical resistance. After firing, it has a perfectly smoothed, smooth, uniform surface that is easy to wash and decontaminate, and resistant to chemical agents, solvents, thermal, and mechanical stress.

It is resistant to the corrosion of acids, alkalis, salts, and solvents at all concentrations, with poor resistance to hydrofluoric acid and strong hot alkalis.

Monolithic stoneware tops have high mechanical resistance, good resistance to thermal shocks, and are non-flammable.

Characteristics comply with DIN 12916 standards. The distinctive features of the monolithic stoneware top are: self-supporting, no joints, high chemical inertia, easy replacement, easy cleaning, decontamination, and pest control.

RISE AND FALL SYSTEM WITH FRONT COUNTERWEIGHT

Steel frame with epoxy coating, plastic sliding guides, and silencer.

6 mm thick safety glass in 3 elements that also slide horizontally.

Aerodynamic handle to optimize the airflow.

Vertical counterweights on the front rectangular deflectors in powder-coated steel, hidden by removable panels (110x110 mm), allowing easy access to the pulleys and the toothed belt.

Allows for the integration of electrical outlets and the hood control panel.

The toothed belt is made of plastic with an anti-friction device for quiet operation.

Safety device (anti-fall system) with immediate locking of the rise-and-fall system in case of imbalance or breakage of the belt.

Mechanical stops at a height of 45 cm with manual unlocking for opening the front panel in compliance with regulations.

FRONT MOUNTED TECHNICAL DRAWER

Integrated technical drawer under the work surface, designed to house gas and fluid faucets, as well as the hood's electronics with separate compartments for each component.

Watertight drawer for optimal protection of equipment in case of accidental liquid spillage.

Ultra-quiet nylon sliding guides ensure almost complete opening of the drawer for easy access to the equipment.

Easy and quick access to the electronics, alarms, electrical and fluid connections through a dedicated and easily accessible compartment (with an included user manual in the drawer), highly appreciated by maintenance teams.

Dimensions: 1800 x 750 mm.

With a polypropylene basin of 300 x 150 mm on the right, raised to avoid accidental discharge of spilled products.

Side panels with Class 0 CP glass.

Large 6 mm shatterproof safety glass provides better internal visibility under safe conditions. It can be easily removed from the outside by removing the fixing profiles.

2 EE UNEL 10/16° IP55 outlets and dedicated magnetothermal switch.

Internal LED lighting.

The extraction point is located on the top of the hood: flange/collar with a diameter of 250 mm.

R1100342