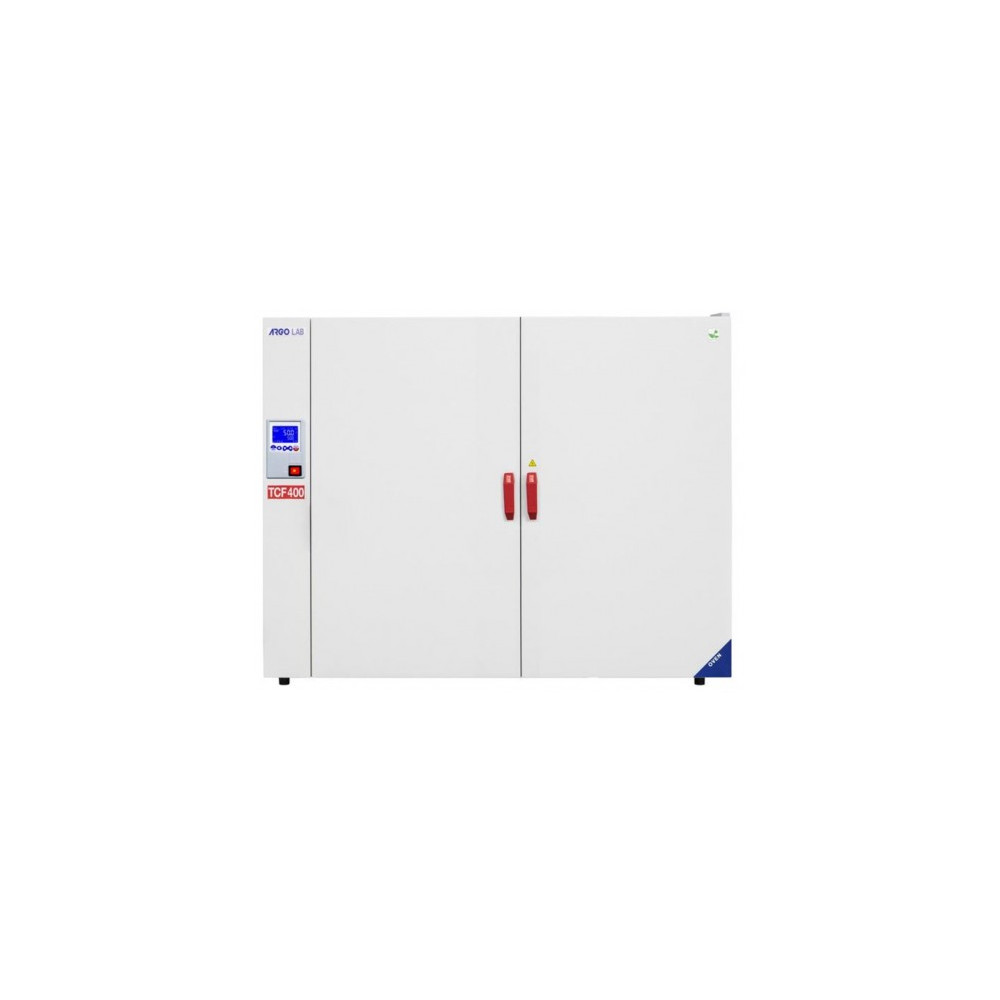

ASEM KRISTAL GREEN FUME HOOD FILTRATION - CLASS 0

close

R1100343

ASEM KRISTAL GREEN FUME HOOD FILTRATION - CLASS 0

All ASEM KRISTAL GREEN FUME HOOD A FILTRATION hoods guarantee effective containment of the enclosure in compliance with the stringent EN 14175 standards.

The containment level defines the hood's ability to retain pollutants inside the enclosure, preventing their dispersion into the laboratory environment.

The effectiveness of containment is demonstrated by tests conducted in accordance with the protocols described in the EN 14175-3, ASHRAE 110:2016, and AFNOR NF X 15-211 (2009) standards (<0.1 ppm SF6).

The containment standards applicable to GreenFumeHood hoods are identical to those of extraction hoods.

Filtration effectiveness according to the NF X 15-211 standard

The Neutrodine® Unisorb filtration technology complies with the NF X 15-211 standard, the most stringent in the industry for molecular filtration, developed by a committee of independent scientists and specialized manufacturers.

This standard applies to filtration hoods (also known as recirculating hoods or ETRAF), designed for research, analysis, and teaching in all laboratories where chemical agents subject to a professional exposure limit (TLV or VME) are handled.

This standard imposes performance criteria related to:

• Filtration efficiency

• Containment efficiency

• Airspeed on the face of the hood

HOOD STRUCTURE

• Painted steel frame with epoxy powder coating resistant to acids (outside the suction chamber)

• Back wall and ceiling made of 10/10 mm thick electro-galvanized steel sheet, cold-formed and painted after degreasing treatment, an initial application of epoxy primer, two subsequent applications of thermosetting powders in RAL 9010 white, and a thermal pass through a tunnel at 200°C

• Lateral panel divided into two parts to simplify assembly and maintenance procedures

• Fully glazed side wall for maximum operator visibility

FRONT COUNTERWEIGHT SLIDER

• Steel frame with epoxy coating, plastic sliding guides, and silencer

• 6 mm thick safety glass in 3 elements, which also slide horizontally

• Aerodynamic handle to optimize the suction flow

• Vertical counterweights on the front rectangular deflectors made of epoxy-painted steel, hidden by removable panels (110x110 mm), allowing easy access to pulleys and the toothed belt.

• For easy access during maintenance operations. They also allow integration of electrical outlets and the hood control panel.

• The toothed belt is made of plastic material with an anti-friction device for silent operation.

• Safety device (anti-fall system) with immediate locking of the slider in case of imbalance or belt breakage.

• Mechanical stops at a height of 45 cm with manual unlocking for opening the front panel in accordance with regulations.

TECHNICAL DRAWER FRONT-MOUNTED

• Integrated technical drawer under the worktop, designed to house gas and fluid taps, as well as the hood’s electronics with separate compartments for each component.

• Waterproof drawer for optimal protection of equipment in case of accidental liquid spills.

• Ultra-quiet nylon sliding guides ensure nearly full drawer opening for easy equipment access.

• Easy and quick access to electronics, alarms, and electrical and fluid connections, thanks to a dedicated and easily accessible compartment (with a user manual included in the drawer), highly appreciated by maintenance teams.

BY-PASS AND AIRFOIL-PASS

By-pass and airfoil-pass optimize the hood's suction when the slider is lowered, preventing turbulence inside the hood.

RECOMMENDED ARRANGEMENT OF THE EXTRACTOR HOOD

The available height under the worktop is 690 mm. We offer two types of optional accessories:

• Cabinets with doors, drawers, or a combination of wood and metal on a base.

• Safety cabinets for storing chemicals (fireproof or for corrosive/toxic products).

ILLUMINATION

LED lighting integrated into the first module before filtration.

MOLECULAR FILTRATION – NEUTRODINE UNISORB® FILTER

Neutrodine® UNISORB is the first multi-use molecular filter for laboratory vapors and gases.

The result of Erlab's latest research, the GreenFumeHood is equipped with the new generation of Neutrodine® Unisorb filters.

Developed over 5 years ago by Erlab's research and development laboratory, this new technology has undergone hundreds of tests, from initial material formulation trials to real-world performance validation of these new filters.

Neutrodine® Unisorb greatly enhances the containment capacity of most vapors emitted during laboratory processes.

These improvements are significant for molecules known to be the hardest to retain with conventional activated carbon filters, such as polar VOCs with low molecular weights and low boiling points.

Patented Innovation:

• Anti-settling filtration system: US Patent 7.563.301

• Neutrodine® Unisorb filter: US Patent 12/465.434

Benefits of Neutrodine Unisorb Filtration:

• Solvents, acids, and bases can be treated simultaneously with the same filter.

• Unprecedented retention capacity

• Unique formulation without any carbon blend

• No heavy metal-based impregnation

MOLECULAR FILTRATION TECHNOLOGY

Molecular filtration focuses on pollutants in the form of molecules, such as VOCs (volatile organic compounds), gases, vapors, etc.

The molecules are retained through adsorption, a property of solids to bind certain molecules to their surface.

Activated carbon has been used for over a century for its notable adsorption properties.

Many applications, such as water treatment, atmospheric waste treatment, VOC treatment, solvent recovery, etc., today use various types of activated carbon.

Each application requires a specific type of activated carbon.

Erlab has developed a unique range of activated carbons, dedicated to protecting laboratory personnel from inhalation hazards.

Our extremely strict specifications determine all the characteristics (granulometry, apparent density, hardness, ash content, etc.) that allow us to select and formulate raw materials to ensure the best possible adsorption across a broad spectrum of molecules. These characteristics are rigorously controlled by the protocols described in international standards (ASTM).

However, activated carbon is not the only guarantee of filtration performance. The effectiveness of a molecular filter also depends on its installation and use. Our hoods' compliance with the AFNOR NF X 15-211 standard ensures molecular filtration performance.

Benefits of Chemical Hoods: Reducing Environmental Impact

• Chemical pollutants are captured at the source: no chemical emissions are released into the atmosphere

• Filters made from eco-friendly raw materials and recycled through energy recovery

• Low energy consumption

• Reduction of the building's environmental impact

The containment level defines the hood's ability to retain pollutants inside the enclosure, preventing their dispersion into the laboratory environment.

The effectiveness of containment is demonstrated by tests conducted in accordance with the protocols described in the EN 14175-3, ASHRAE 110:2016, and AFNOR NF X 15-211 (2009) standards (<0.1 ppm SF6).

The containment standards applicable to GreenFumeHood hoods are identical to those of extraction hoods.

Filtration effectiveness according to the NF X 15-211 standard

The Neutrodine® Unisorb filtration technology complies with the NF X 15-211 standard, the most stringent in the industry for molecular filtration, developed by a committee of independent scientists and specialized manufacturers.

This standard applies to filtration hoods (also known as recirculating hoods or ETRAF), designed for research, analysis, and teaching in all laboratories where chemical agents subject to a professional exposure limit (TLV or VME) are handled.

This standard imposes performance criteria related to:

• Filtration efficiency

• Containment efficiency

• Airspeed on the face of the hood

HOOD STRUCTURE

• Painted steel frame with epoxy powder coating resistant to acids (outside the suction chamber)

• Back wall and ceiling made of 10/10 mm thick electro-galvanized steel sheet, cold-formed and painted after degreasing treatment, an initial application of epoxy primer, two subsequent applications of thermosetting powders in RAL 9010 white, and a thermal pass through a tunnel at 200°C

• Lateral panel divided into two parts to simplify assembly and maintenance procedures

• Fully glazed side wall for maximum operator visibility

FRONT COUNTERWEIGHT SLIDER

• Steel frame with epoxy coating, plastic sliding guides, and silencer

• 6 mm thick safety glass in 3 elements, which also slide horizontally

• Aerodynamic handle to optimize the suction flow

• Vertical counterweights on the front rectangular deflectors made of epoxy-painted steel, hidden by removable panels (110x110 mm), allowing easy access to pulleys and the toothed belt.

• For easy access during maintenance operations. They also allow integration of electrical outlets and the hood control panel.

• The toothed belt is made of plastic material with an anti-friction device for silent operation.

• Safety device (anti-fall system) with immediate locking of the slider in case of imbalance or belt breakage.

• Mechanical stops at a height of 45 cm with manual unlocking for opening the front panel in accordance with regulations.

TECHNICAL DRAWER FRONT-MOUNTED

• Integrated technical drawer under the worktop, designed to house gas and fluid taps, as well as the hood’s electronics with separate compartments for each component.

• Waterproof drawer for optimal protection of equipment in case of accidental liquid spills.

• Ultra-quiet nylon sliding guides ensure nearly full drawer opening for easy equipment access.

• Easy and quick access to electronics, alarms, and electrical and fluid connections, thanks to a dedicated and easily accessible compartment (with a user manual included in the drawer), highly appreciated by maintenance teams.

BY-PASS AND AIRFOIL-PASS

By-pass and airfoil-pass optimize the hood's suction when the slider is lowered, preventing turbulence inside the hood.

RECOMMENDED ARRANGEMENT OF THE EXTRACTOR HOOD

The available height under the worktop is 690 mm. We offer two types of optional accessories:

• Cabinets with doors, drawers, or a combination of wood and metal on a base.

• Safety cabinets for storing chemicals (fireproof or for corrosive/toxic products).

ILLUMINATION

LED lighting integrated into the first module before filtration.

MOLECULAR FILTRATION – NEUTRODINE UNISORB® FILTER

Neutrodine® UNISORB is the first multi-use molecular filter for laboratory vapors and gases.

The result of Erlab's latest research, the GreenFumeHood is equipped with the new generation of Neutrodine® Unisorb filters.

Developed over 5 years ago by Erlab's research and development laboratory, this new technology has undergone hundreds of tests, from initial material formulation trials to real-world performance validation of these new filters.

Neutrodine® Unisorb greatly enhances the containment capacity of most vapors emitted during laboratory processes.

These improvements are significant for molecules known to be the hardest to retain with conventional activated carbon filters, such as polar VOCs with low molecular weights and low boiling points.

Patented Innovation:

• Anti-settling filtration system: US Patent 7.563.301

• Neutrodine® Unisorb filter: US Patent 12/465.434

Benefits of Neutrodine Unisorb Filtration:

• Solvents, acids, and bases can be treated simultaneously with the same filter.

• Unprecedented retention capacity

• Unique formulation without any carbon blend

• No heavy metal-based impregnation

MOLECULAR FILTRATION TECHNOLOGY

Molecular filtration focuses on pollutants in the form of molecules, such as VOCs (volatile organic compounds), gases, vapors, etc.

The molecules are retained through adsorption, a property of solids to bind certain molecules to their surface.

Activated carbon has been used for over a century for its notable adsorption properties.

Many applications, such as water treatment, atmospheric waste treatment, VOC treatment, solvent recovery, etc., today use various types of activated carbon.

Each application requires a specific type of activated carbon.

Erlab has developed a unique range of activated carbons, dedicated to protecting laboratory personnel from inhalation hazards.

Our extremely strict specifications determine all the characteristics (granulometry, apparent density, hardness, ash content, etc.) that allow us to select and formulate raw materials to ensure the best possible adsorption across a broad spectrum of molecules. These characteristics are rigorously controlled by the protocols described in international standards (ASTM).

However, activated carbon is not the only guarantee of filtration performance. The effectiveness of a molecular filter also depends on its installation and use. Our hoods' compliance with the AFNOR NF X 15-211 standard ensures molecular filtration performance.

Benefits of Chemical Hoods: Reducing Environmental Impact

• Chemical pollutants are captured at the source: no chemical emissions are released into the atmosphere

• Filters made from eco-friendly raw materials and recycled through energy recovery

• Low energy consumption

• Reduction of the building's environmental impact

R1100343